Preparing for the future

As Pratt & Whitney(P&W) commemorates its 100th anniversary this year, the company can take pride on a century of innovation even as it works to bring advancements to the the next generation of single-aisle aircraft. Rob Griffiths, Senior Vice President, Commercial Engines Operations, Pratt & Whitney explains how the company is actively exploring technologies such as composite fan blades, reduced core sizes, ceramic matrix composites, and hybrid-electric propulsion to further enhance the groundbreaking efficiency of modern engines.

What are some of the key trends that Pratt & Whitney is witnessing from airlines customers/lessors on engine requirements?

We continue to see strong demand for the GTF, with a growing orderbook of 11,000 customers, and the GTF Advantage will help us meet that demand as it becomes the production standard over the next few years. Our customers remain focused on durability and fuel efficiency, and the GTF Advantage will deliver improvements in both categories, among others. At the same time, we’re also working to improve the durability of the current GTF engine through block upgrades and by offering the GTF Advantage hot section as a retrofit option in the future.

How is Pratt & Whitney addressing global supply chain challenges to ensure resilience and timely delivery of engines and MRO services?

We’re continuing to see steady improvements in our supply base. For example, in Q1, structural castings at Pratt & Whitney were up 16% year-over-year and PW1100 MRO was up 35% year-over-year, and we remain on track for over a 30% improvement for the full year.

While we are seeing improvements, industry-wide supply chain pressures continue to affect material availability. Pratt & Whitney has taken several actions to increase supply chain output, including embedding engineers, quality and delivery assurance professionals with key suppliers to address challenges real-time helping to accelerate the delivery of parts, as well as continuing to qualify additional suppliers on key programs expanding value stream capacity. All of these initiatives are reflected in the execution of our CORE operating system, which is a common set of methods and tools to improve processes and deliver on customer commitments.

We are also focused on developing new part repairs to reduce dependency on current material constraints. In April, we announced a new solution to enable repair to GTF structural case features using a 3D printing method known as Directed Energy Deposition. By eliminating several steps in the current repair method, this new technology reduces overall process time by more than 60 per cent.

How does the GTF Advantage engine enhance Pratt & Whitney’s market position and deliver value to customers through improved efficiency and performance?

The GTF Advantage is a great example of how we continually innovate to deliver value for our customers, incorporating all the learnings from the first 10 years of the GTF engine and service. It will offer 4% more takeoff thrust at sea-level airports and 8% more at high-altitude airports; up to twice the time on wing compared to the current engine; and better fuel efficiency. In addition, the GTF Advantage will be fully intermixable and interchangeable with today’s GTF engine model and we remain on track to ship the first production engines to Airbus later this year, with entry into service anticipated in 2026. With its higher takeoff thrust capability, the GTF Advantage is also especially well-suited for the A321XLR variant and, once in service, will help that platform open up new routes and better operating economics for airline customers.

Building on the GTF’s efficiency gains, what innovative propulsion technologies is Pratt & Whitney exploring to meet future aviation needs?

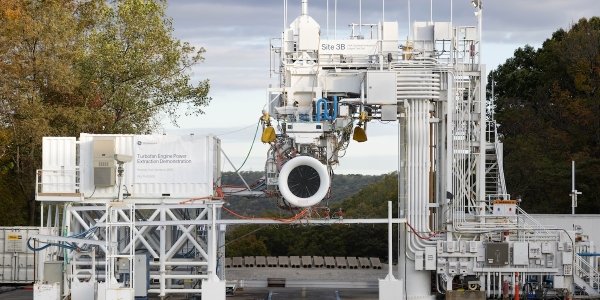

As Pratt & Whitney celebrates its centennial this year, we’re looking back on our 100-year history of innovation, but also looking forward to the next 100 years. For next-generation single aisle, we believe the GTF architecture is the right choice to enable significant improvements in performance while ensuring the right durability and maturity for our customers. We continue to look at technologies such as composite fan blades, smaller cores, ceramic matrix composites and hybrid-electric propulsion to further improve the game changing efficiency of today’s engines. By the time we come to the mid-2030s, the GTF architecture will have accumulated around 250 million hours of flying time, critical experience which underpins our strategy for the next generation.

What steps is Pratt & Whitney taking to expand sustainable aviation fuel (SAF) adoption across its engines, and what are the key milestones planned for SAF integration?

All Pratt & Whitney engines and Collins Aerospace fuel management systems are certified to operate with approved synthetic fuel blends of up to 50% with conventional aviation fuel. The company is also preparing its products for future fuel specifications for 100% synthetic fuel use. This effort includes a comprehensive engine testing program and collaboration with industry associations such the Commercial Aviation Alternative Fuels Initiative (CAAFI) and the International Aerospace Environmental Group (IAEG). To date, nine different engine models, including GTFA, and three auxiliary power units (APU) have been tested as compatible with 100% synthetic fuel.

What role do strategic relationships play in Pratt & Whitney’s strategy to deliver innovative and sustainable engine solutions?

Strategic relationships are integral to our ability to best serve our customer base. When it comes to the GTF, for example, we have several industrial partners, including MTU, IHI Corporation, Mitsubishi Heavy Industries, Kawasaki Heavy Industries, Hanwha, ITP Aero and GKN. They are fully integrated into our network, both in terms of OEM capabilities and MRO capacity.

How is Pratt & Whitney addressing the global demand for skilled aviation professionals to support the maintenance and operation of its advanced engine technologies?

There is strong demand and competition for aviation personnel across the industry. We are focused on making lifelong learning part of the ethos of our company, offering on-the-job training and structured training programs that include employee scholarships for those who want to study at the tertiary level whether it be polytechnic, technical school or university. As engine technology evolves, these new technologies will dramatically alter the industry.